Victor, a customer from Russia, was looking for a machine that could remove leaves from blueberries. After a series of discussions and consultations with our engineering team, we recommended our bubble washing machine, which best suited his specific leaf removal needs. Victor now uses this washer, achieving high washing efficiency and significant water savings. He is so satisfied with the results that he has decided to become our long-term loyal customer.

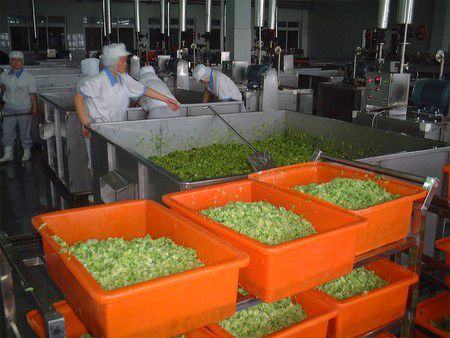

Kham, who runs a successful food processing factory in Vietnam, has relied on Walley for more than ten years to equip his operation with the latest in freezing technology. From pretreatment equipment to freeze dryers, his factory is a true showcase for our wide range of products. Thanks to their confidence in the quality and efficiency of our fruits and vegetables processing equipment, Kham has become a repeat customer, placing orders every year, regardless of size.

In 2020, we designed a customized drying line for a U.S. factory specializing in the production of high-quality meats. The main equipment of this line is a three-level belt-type dryer, optimized for steam operation. Doni, along with his colleagues Joshua and Jacqueline, have become not only key collaborators, but also close friends of our company. We have established an ongoing commitment to after-sales support that has been highly valued by our team of friends in the U.S. We are excited about the prospects for future collaborations.

Khen Alexander, from Kazakhstan, made his first contact with us during our National Day vacation in 2022. Known for his thoroughness in business and hard work, after several months of intense deliberations, we managed to develop a proposal that perfectly matched the needs of his factory. This collaboration marked the beginning of our partnership, also granting him the rights to distribute our products in Kazakhstan.

Today, Khen has positively validated and appreciated both our food processing machines and our services. During his usage experience, he has offered valuable criticism and suggestions for improvements, which we have humbly received and are seriously considering. We remain in constant dialogue with him regarding his planned second production line and new projects for processing other types of vegetables and fruits.

We met Mr. Mansur, a dear friend from Uzbekistan, on June 1, 2016 at a bus station, an unexpected place that marked the beginning of our transnational friendship. He is fluent in Chinese and often acts as a translator for his Uzbek clients. Mr. Mansur has accompanied several clients to our company repeatedly, from initial factory visit to project confirmation, price negotiation, machine inspection, container loading and on-site installation. He is meticulous and conscientious in his work. Pictured here is a fruit and vegetable drying project in Qarshi, Uzbekistan, with a capacity of 2 tons per hour, a typical example of the many drying projects Mr. Mansur has helped to complete.

From Nisporeni, Moldova, Mr. Vasile, owner of an extensive orchard, has always been in search of the most suitable machinery to process his plums and prunes. After extensive research, in 2016, he decided to personally visit our company to discuss processing solutions. After two days of meticulous planning and reviewing details, we signed our first contract. The photo captures the beginning of a fruitful collaboration. Thanks to the in-depth technical knowledge of our engineers and our ability to tailor our solutions to the customer's specific needs, Mr. Vasile found the perfect machines. Four years later, he reaffirmed his confidence in us with a second order, cementing a long-term relationship of trust and mutual cooperation.

From Australia, Michael Jolley connected with our company after finding us online. With a particular interest in tailoring our solutions to his needs, Michael sent us a special sample of Australian carobs for specific testing. Responding to his unique request, one of our most experienced engineers customized the design of our belt dryer, achieving a performance that exceeded Michael's expectations. His satisfaction with the result has led to ongoing discussions about future equipment purchases.