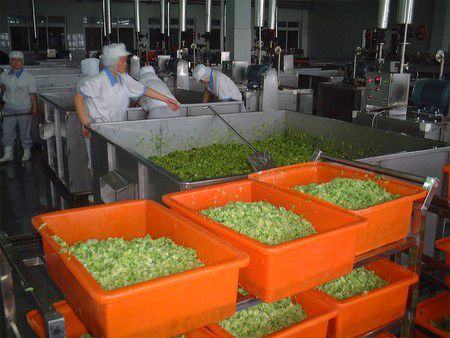

You want your food processing lines to efficiently process products according to your specifications. Food needs to be graded & separated, washed, cut, blanched, cooled, and unloaded. By having these procedures carried out in a single production line, efficiency can be greatly increased. Walley provides perfect food production solutions that can handle every type of produce - from loading to unloading. These fruit and vegetable processing lines can be fully customized to meet all of your requirements.

Walley has nearly 27 years of industry experience and owns sister companies such as Sunshine Steel Structure and Shundi Foods, providing comprehensive services covering from factory construction, equipment layout design and manufacturing, to food processing. Walley is dedicated to providing food processing solutions to address your equipment-related issues.

-

- Cabbage Dehydrating Processing Line Cabbage dehydrating processing line is an efficient and automated food processing system consisting of multiple pieces of equipment that work in an orderly manner. More

-

- Carrot Dehydrating Processing Line Carrot dehydrating processing line is an automated food processing system specifically designed for handling carrots. More

-

- Onion Dehydrating Processing Line Onion dehydrating processing line can process 2 tons of fresh onions per hour and can be customized according to customer production requirements, meeting the needs of large-scale mechanized onion production. More

-

- Green and Red Bell Pepper Dehydrating Processing Line Green and red bell pepper dehydrating processing line features high automation and can process 2 tons of fresh peppers per hour. More

-

- Asparagus Lettuce Dehydrating Processing Line We also offer customized equipment tailored to meet your specific production requirements, enabling large-scale mechanized production of asparagus lettuce. More

-

- Sweet Corn Freezing Processing Line Grain processing enterprises, IQF food processing enterprises, and catering food processing enterprises. More

-

- Frozen French Fries Production Line Frozen French fries production line is operated on a conveyor system, featuring high automation and capable of processing 2 tons of French fries per hour. More

-

- Soybean Freezing Processing Line It can process 1 ton of soybeans per hour and can be customized according to customer production requirements to meet large-scale mechanized production of soybeans. More

-

- Okra Freezing Processing Line This production line can be customized according to customer production requirements to meet large-scale mechanized production of okra. More

-

- Green Pea Freezing Processing Line This production line can be customized according to customer production requirements to meet large-scale mechanized production of green pea. More

-

- Clean Vegetable Processing Line Clean vegetable processing line consists of cleaning, sorting, and air knife dewatering machines. More

-

- Raisin Washing and Dehydrating Production Line This production line can be customized according to customer production requirements to meet large-scale mechanized production of raisin. More

-

- Prune Washing and Disinfecting Production Line Prune washing and disinfecting production line is fully automated, with a capacity of 1 ton per hour. More

- Engineering and Design

Our professional engineering team provides a comprehensive range of services, including factory layout, equipment design, manufacturing, installation and commissioning, as well as personnel training. We specialize in a wide variety of equipment, such as freeze-drying equipment, hot air dryers, IQF freezers, and pre-treatment equipment. Our expertise extends to various industries, including fruit and vegetable processing, agricultural product processing, aquatic product processing, traditional Chinese medicine, and chemical industries. - Process Knowledge

With nearly 27 years of experience, Walley can recommend the most suitable equipment based on different processes, helping clients maximize their benefits. - Project Management

From customer inquiries to equipment shipment, we have professional staff tracking project progress to ensure real-time control of equipment quality. - Installation and Training

We have a professional engineering team to provide on-site installation services for customers. Different installation plans are provided according to different projects. Upon completion of installation, professional training will be provided to operators for better operating and maintaining the equipment, thus extending the service life.

-

Venezuela Onion, Carrot Dehydrating Processing Line

-

Uzbekistan Green and Red Bell Pepper Dehydrating Processing Line

-

Uzbekistan Carrot Dehydrating Processing Line

-

Tajikistan Onion Dehydrating Processing Line

-

Nigeria Spices Dehydrating Processing Line

-

Vietnam Shrimp And Other Seafood Dehydrating Processing Line

-

Zhejiang Lettuce Dehydrating Processing Line

-

Kale Dehydrating Processing Line

-

Azerbaijan Strawberries, Blueberries And Other Fruit IQF-Freezing Equipment

-

Algeria Soybean Freezing Processing Line

-

Indian Okra Freezing Processing Line

-

Thailand Sweet Corn Freezing Processing Line

What type of food processing line do you require? Kindly inform us of your needs and Walley will provide a personalized equipment quotation that meets your specific requirements. Would you like to learn more about our food processing solutions or do you have any inquiries? Please feel free to contact us at and we will gladly address all your concerns.